The logistics market requires faster and more efficient solutions to satisfy the customers’ needs. This is why understanding the cross-docking transport advantages and disadvantages through warehousing examples is important to use its benefits in your favor.

Jump to:

- What does cross-docking mean?

- Cross-docking warehouse example

- Types of cross-docking transport

- Cross-docking advantages

- Cross-docking disadvantages

- Dropshipping vs. cross-docking

What does cross-docking mean in shipping?

You can better understand the cross-docking transport services by first, having a look at the inbound and outbound logistics operations.

- The process starts when the company distributes the freight from the supplier or manufacturer and distributes them to the user by trucks, semi-trailers or rail.

- The freight arrives at the warehouse or the cross-dock terminal where it is sorted from many different vehicles. The products, or materials, are sorted out to identify the final destination.

- Once the freight is sorted, it is docked onto the vehicles acting as part of the outbound logistics process, or transported to the end-customer.

These steps are showing a cross-docking warehouse example, and the primary purpose the company uses this strategy is to lower the amount of inventory at the facility. With this practice, the materials, or products inventory time at the facility is minimal or non-existent due to the almost immediate outbound transport. The usual time the freight stays at the warehouse is less than 24 hours.

You may want to continue reading about:

- Inbound and outbound logistics

- Pallet delivery in Europe

- Less than truckload transport

- Full truckload transport

Before companies implemented cross-docking transport services within their processes, the process was executed by Less than Truckload services which were resulting in longer delivery times. With previous planning, the whole truck is filled with goods to be delivered to a destination.

You should join the thousands of companies that have chosen us as the trusted connection between the carriers and the companies. Our vast network of carriers allows us to meet every need you have reliably and at the same time, with lower costs. Are you interested to learn more about Full Truck shipping services through Eurosender?

Cross-docking warehouse example

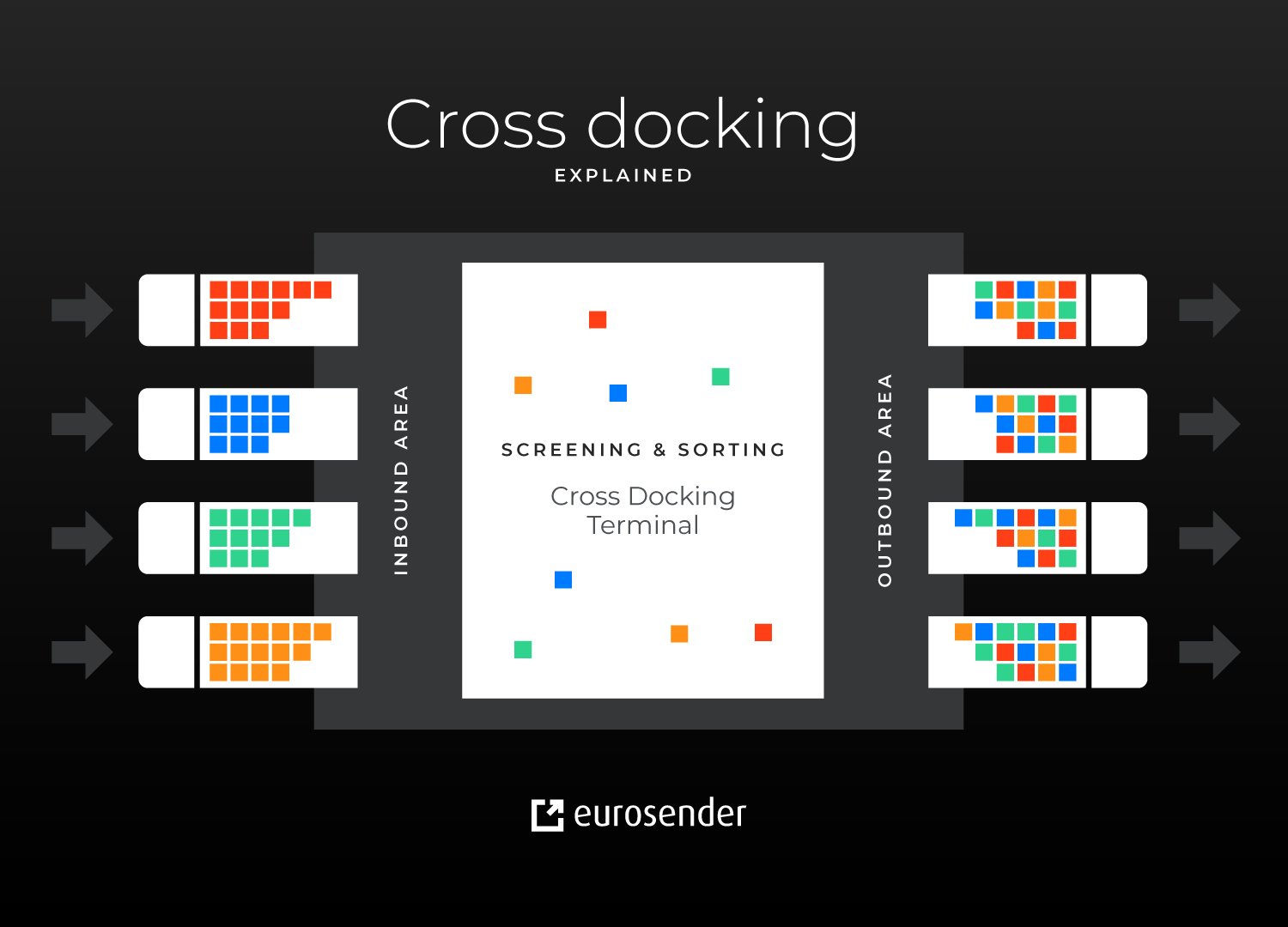

To understand better the process, we will show you a cross-docking warehouse example through the following visual.

Types of cross-docking transport

With what we have previously pointed out, we can see two types of cross-docking transport:

- Pre-distribution process – In this phase, the goods are identified, unloaded, and sorted out according to previous supplier instructions.

- Post-distribution process – The products leave the facility to be distributed to the end-customer.

Check out the following logistics terms:

Cross-docking transport advantages and disadvantages

Cross-docking transport advantages

- Lower inventory handling as material handling will be streamlined, resulting in greater efficiency.

- Less time at the warehouse as the cross-dock facility manages to keep almost no storage due to the fast outbound movement.

- Lower storage costs as it’s the case with the traditional warehouses.

- Lower transport costs due to the pre-planned destination points with filled full truck capacity.

- Faster delivery to the end-customers due to the accelerated screening processes.

Cross-docking disadvantages

- Material handling requires computerised logistics systems.

- A high volume of materials is needed to result in lower costs.

- The need for adequate carriers to transport the freight.

Check out our popular shipping routes:

Dropshipping vs cross-docking

- Dropshipping is different from the cross-docking warehouse example as in the dropshipping case – the supplier keeps the inventory at their facility. Once the supplier gets the order from the seller, they ship the product to the end-consumer.

- Cross-docking, on the other hand, minimises the time the inventory is kept in a warehouse. The supplier sends the materials to the cross-dock facility, and they are then transported to the end-customer.

You may be interested in the following articles: